Project ZEER! Evaporative Cooling to Reduce Food Waste in India

In the Spring of 2014, as part of an MIT Sloan School of Business class known as New Enterprises, I worked on a team to develop both a technology to reduce food waste in India, as well as a detailed business plan to commercialize the concept. The project, known as Project ZEER!, is a high performance evaporative cooling system purposefully designed to address food spoilage problems due to lack of infrastructure, distance- to-market, and refrigerated fleet vehicles.

Thirty percent (30%) of India’s food supply spoils before consumption. This creates a horrific problem within the food supply system where solutions are sought. The volume of food that spoils while trying to feed 1.4 billion people is unimaginable. India wastes more grain each year than Australia produces, and more fruits and vegetables than the U.K. consumes.1 Fortunately, Project Zeer! was designed to address this problem head-on. It spans the entire supply chain- from harvest to home.

Heat is the #1 enemy. With harvest area temperatures exceeding 115°F/46°C, cooling the food by 15°- 20°F greatly extends the shelf life of highly perishable foods (in the case of tomatoes and carrots, from 2 to 20 days!). Project Zeer! provides cooling, not refrigeration. There are no moving parts. Units are extremely rugged. And, they operate 24×7 unattended. Daily temperature and dew point variations are well suited to evaporative cooling.

Distance-to-Market and Time-to-Market also contribute to the spoilage problem. Farmlands are typically located long distances from markets. Due to poor road infrastructures, the distance is measured in days. Transit times of 3-days are not uncommon. Once harvested, the food spoilage clock begins ticking. Everyone is affected, not just the poor.

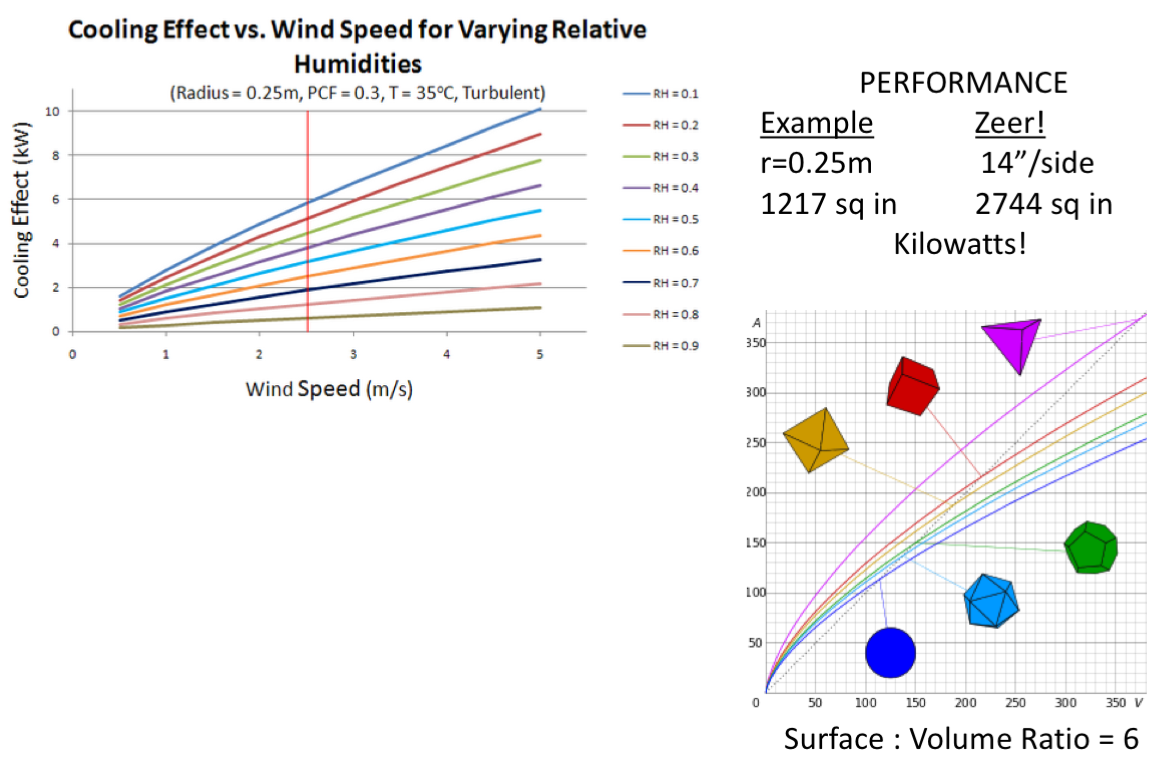

Technically, Project Zeer! uses evaporative cooling. It was designed and studied at MIT in Cambridge, Massachusetts. It exploits the laws of Latent Heat of Vaporization to provide large amounts of cooling using only water. The evaporative media hold enough water to last a 3-day journey and is an excellent insulator when dry- thus preserving the cooled contents inside from external heat. The prototype system works extremely well and forms the basis of our technical model. Each unit holds 35 liters (a standard unit of food sales by volume), are a 1-person “lift” even when full, can be stacked 10 units high, and self-wet when stacked for unprecedented efficiency. Contents remain untouched and therefore unbruised, further extending the shelf life.